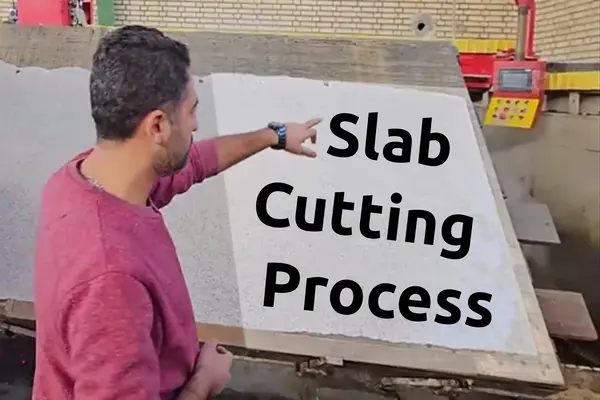

Slab Cutting Process with Gantry Cutting Machine

Slab cutting process using a gantry cut machine is one of the critical stages in preparing building stones, executed with great accuracy and meticulous attention to detail.

Slab Stone Cutting stages:

1/ Placing the Slab on the Machine:

First, the selected slab stone is carefully lifted using a crane and gently placed on the gantry cut machine. After that, the stone is securely fixed to ensure it remains completely stable during the slab cutting process.

2/ Blade Adjustment:

The diamond blade of the machine is adjusted according to the thickness and type of stone. This optimization enhances the cutting process, enhancing both precision and speed.

3/ Adjustment of Cutting Dimension:

The required cutting dimensions are entered into the machine, which then uses its integrated laser to precisely pinpoint the cutting areas.

4/ Starting the slab cutting process:

The machine starts the slab cutting process with a CNC disk and pre-configured setting. The precision during this stage guarantees a neat and flawless outcome.

5/ Attention to Stone Waste:

A crucial aspect of slab stone cutting is choosing a direction that results in minimal stone waste. The machine uses a laser to identify the uneven parts of the slab and starts cutting from those points.

Final Conclusion:

This cutting method produces slab stones with exact dimensions, smooth edges, and superior quality. The high level of precision not only reduces stone waste but also enhances the efficiency of building stone usage.

Publish on:

April 6, 2025

Updated on:

April 19, 2025